Simple process automation

Linear technology can be used for numerous transport tasks. Preconfigured solutions such as the ones offered by item simplify the complex interplay between linear unit, motor, gearbox and controller. This minimises the workload involved in researching and designing the ideal linear unit complete with drive components. What’s more, these systems are perfectly coordinated and have universal interfaces. Thanks to intelligent software, the linear units can be configured and commissioned in no time at all.

Combining flexible selection with ultra-simple design and commissioning, the building kit system from item offers the ideal linear technology for virtually any transport task. The item linear motion unit® automation system provides users with a comprehensive turnkey solution comprising linear unit, motor, gearbox and controller. The web-based item MotionDesigner® and item MotionSoft® software programs are also incorporated. When it comes to using the self-learning linear units, customers select and combine appropriate components then independently commission the linear system, which has been produced and preconfigured in line with their requirements. “Our item linear motion unit® system makes it easy to dimension, handle and commission linear technology,” says Johannes Sodermanns, product manager for machine automation at item. “Users don’t need to be specialists in linear or control technology, because the software incorporates expertise in these areas,” he adds.

Ideal configuration of linear technology

item MotionDesigner® selects the data required for the transport task from a range of coordinated components (motors, gearboxes, controllers and accessories). Parameters that go much further than straightforward technical details and are the result of comprehensive calculations and measurements are also built in. During the design process, the tool takes into account the required level of repeatability, the on-site electrical supply and the ambient conditions. Factoring in this data, the intelligent software works out an ideal combination of individual components. This can involve as many as two million calculations. The result is available in seconds, and the tool recommends a customised linear unit. It also indicates what useful accessories are available.

Rapid commissioning

Thanks to item MotionSoft® software, the system can be commissioned in next to no time. The installation software and controller use data that already exists for the specified components. All these components are coordinated with each other. The software installs the entire linear technology system independently – the tool checks all available data imported from item MotionDesigner® and calculates the correct controller settings for automatic start-up of the item linear motion unit®. This saves a great deal of time, as there is no need for users to compile this data themselves. Thanks to the programmable motion profiles that can be stored in the controller, many transport tasks can be carried out without the need for a PLC. However, users still have the option of connecting the solution to a PLC via the standard fieldbus interfaces.

Maximum flexibility

“Our linear technology offers maximum flexibility,” emphasises Sodermanns. “Users can design their solutions independently, selecting appropriate components and suitable drive technology from our building kit system, or they can opt for preconfigured linear units,” he continues. In this way, they obtain solutions that meet their needs down to the last little detail. The item linear motion unit® turnkey automation solution saves users a lot of steps that are required when utilising market-standard automation solutions. For example, it is also possible to quickly check whether a particular linear unit is suitable for a new transport task. Another advantage is the comprehensive product documentation, including assembly information, that is provided when using this automation solution. The system has universal interfaces, too, meaning components from other manufacturers can be incorporated. Connection to PC-based engineering systems such as LabVIEW is also possible.

The end result – a far easier process

The two software solutions from item ensure transport tasks can be mapped quickly and easily in linear solutions. They also make commissioning preconfigured linear units a straightforward process. item MotionDesigner® factors in all data, technical parameters and dynamic requirements to produce the ideal solution, adapted optimally to the specific needs, in next to no time. item then supplies this turnkey solution preconfigured and ready to install straight away. With item MotionSoft®, commissioning takes just a few minutes. Using the item linear motion unit® system therefore saves users a great deal of time and effort. The design and commissioning process is made far easier. What’s more, the free online software coordinates the components with the actual project requirements, which ensures all aspects are taken into account. This prevents the task from becoming unnecessarily complex and minimises the risk of design flaws.

As at:19 April 2023

Length: 5,526 characters including spaces

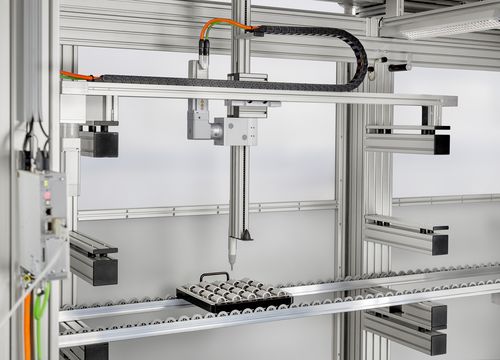

Image 1: Overview of the item linear motion unit® system

Image 2: The linear system in use

Image 3: Commissioning an item linear motion unit®

Caption 1: The full linear motion unit® system from item comprises linear units, gearboxes, motors, controllers, cables and accessories.

Caption 2: The design of the automation system and the specific controller settings are determined according to customer requirements.

Caption 3: item MotionSoft® software ensures the turnkey solution can be commissioned automatically and within a few minutes.