Efficient material supply

Efficient supplies of materials at the perfect tempo – tugger trains are used in many areas of logistics and production. The Engineeringtool from item now offers the option of digitally designing customised tugger trains and thus ensuring a demand-based material flow. Stable basic frames and structures can be rapidly created from the numerous components in the item MB Building Kit System and item Lean Production Building Kit System and adapted with ease.

Many automotive and mechanical engineering companies and logistics service providers use tugger trains to make materials available for their production operations on a just-in-time basis. These tugger trains consist of a towing vehicle and several trailers – tugger train trolleys. The trolleys are used to transport goods and production equipment in load carriers from the storage facility to their destinations. As the transported goods vary in size, weight and shape, the tugger trains need to be optimised accordingly.

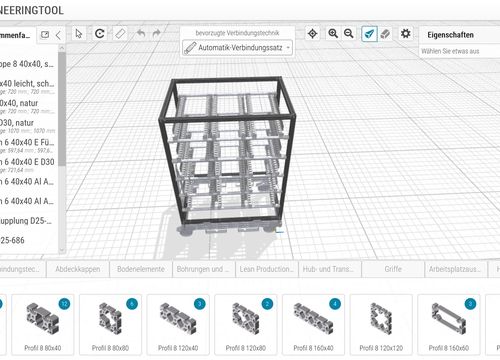

Ultra-easy design thanks to the item Engineeringtool

The item building kit system philosophy makes it possible to design stable and robust tugger trains of numerous types. The item Engineeringtool provides the ideal digital support in this process. Users deploy the intelligent software to quickly and easily design custom trolleys and load carriers using item aluminium profiles, matching fasteners and other accessories. Whether it be standard constructions, for example for europallets or mesh crates, or customised tugger train solutions, the engineering program offers countless design options for basic frames and structures. Thanks to the modular concept, tugger trains can be flexibly extended or modified at any time. All components are coordinated with each other and can be used together in a range of combinations.

Wide selection of components

Users assemble their custom tugger train in the item Engineeringtool from the countless components available. These include Swivel and Fixed Castors from the item MB Building Kit System, which offer features such as optimum rolling properties and a load-carrying capacity of up to 500 kilograms. They ensure optimum handling and outstanding directional stability for the trolleys. item offers a variety of different Drawbar designs for connecting several trolleys together or with the towing vehicle. This makes it possible to connect to commonly used coupling systems in electrical towing vehicles and to automated guided vehicles. Other components, including the Stacking Guide, Corner Deflector Guard and Forklift Pocket, enable users to adapt frames to various load carriers. What’s more, large numbers of components from the item Lean Production Building Kit System are available to ensure an efficient material supply in line with the lean philosophy. For all engineering results, the item Engineeringtool also provides the installation guide and full project documentation. On completion, the entire construction can be ordered as a project through the Online Shop.

Length: 3,182

Date: 4 January 2021

Photos: 2 (source: item)

Caption 1: Users deploy the item Engineeringtool to quickly and easily construct custom trolleys and load carriers using item aluminium profiles, matching fasteners and other accessories.

Caption 2: In addition to various Fixed and Swivel Castors, the Forklift Pocket, Stacking Guide and Corner Deflector Guard, item offers a variety of different designs for Drawbars that can be used for optimally connecting tugger train trolleys with each other and with the towing vehicle.